Steel Shot Blasting for Efficient and Durable Surface Preparation

Steel Shot Blasting can be classified as one of the most influential and efficient surface treatment processes in the modern manufacturing and fabrication industries. It consists of the use of spherical steel media that are shot at high speed for the purpose of cleaning, hardening, or preparing metal surfaces. The use of the latest blasting systems allows for the uniform and complete removal of rust, mill scale, paint, and other surface contaminants, resulting in the creation of cleaner and more uniform finishes. The application of this method not only leads to better surface quality but also results in improved coating adhesion and longer metal parts life. Due to its capability of delivering uniform and regulated output, steel shot blasting has remained the go-to process in the areas of automotive, foundry, shipbuilding, infrastructure, and heavy engineering applications.

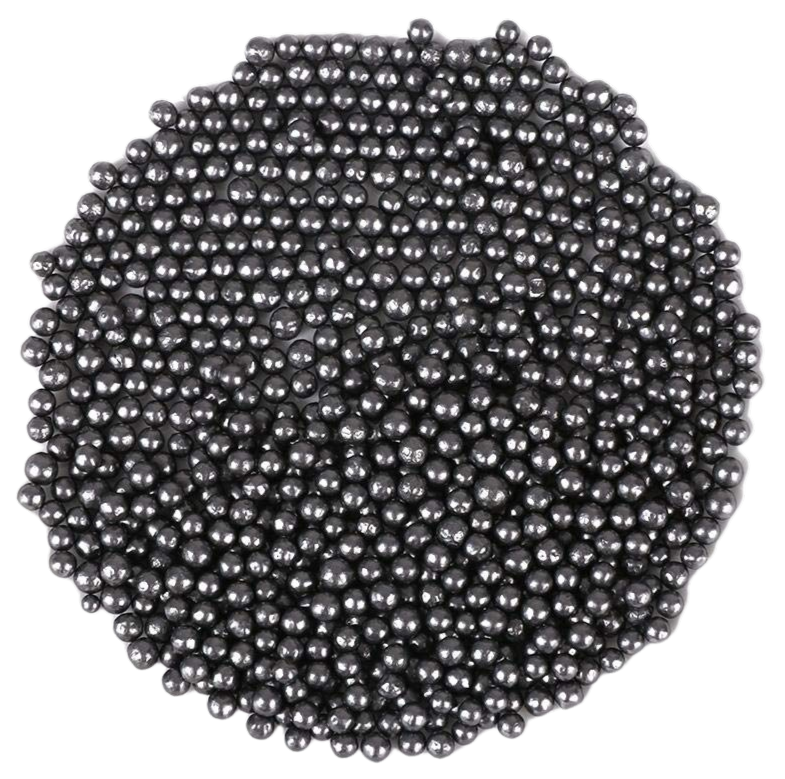

The main characteristic of steel shot blasting which is a process mostly aimed at everything needed for durability, uniformity and optimal impact strength, is high-quality cast steel shot. The cast steel shot’s round shape provides even distribution of the material and good energy transfer, thereby making cleaning and shot peening processes more efficient. Steel shots, as performance-driven abrasives, have longer operational life, less dust generation and media consumption, thus, the use of such materials assures better surface finishes and increased resistance to fatigue in components even in the case of high-volume or continuous blasting. We help industries to reach perfect surface preparation and at the same time to maintain efficiency of the process by selecting the right grade and size of cast steel shot.

Our steel shot blasting method has quality, uniformity, and durability as its main characteristics. The abrasives that we employ go through an extensive quality check process that covers hardness, size distribution, and structure. As a result, we can handle a broad spectrum of industrial requirements—from large-scale rust removal of steel structures to surface preparation for coating or painting. With the combination of technical expertise and reliable production standards, we offer our clients not only blasting performance but also lower total operating costs. Steel-shot blasting solutions will bring the industry the ability to create stronger surfaces, higher productivity, and consistent results that meet very high operational standards.